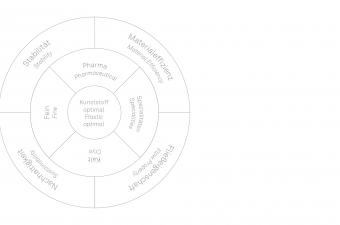

Optimal plastic powders

We understand our craft. And that of our customers.

Our experience shows that raw plastic only brings its true value to bear through specific grinding and finishing. That's why our vision is "Always the right powder for you". Our specialities are cold grinding and fine grinding, as well as finishing for the pharmaceutical industry and for special applications such as additive manufacturing/3D printing. We are integrated into our customers' processes right from the start, so we understand exactly what they need - and what they might need in the future. With the right process for a certain raw material, plastic powders are made more stable, for example, their flow properties and material efficiency are improved, and ecological sustainability increased. This results in fewer work and cleaning steps, trouble-free further processing, fewer rejects, greater energy and material efficiency and lower costs.

Cold grinding

We're the pros

Cold grinding, also known as cryogenic grinding, makes it possible to grind soft, flexible, moist or sticky materials that would therefore be impossible to adequately grind using conventional methods. With this process, such starting materials are temporarily hardened using liquid nitrogen at temperatures well below -50° Celsius. In this state, they can be finely ground without sticking together or melting. Even highly sensitive substances are protected from oxidation and thermal stress.

Fine grinding

We make small grains into big business

Depending on the raw material and customer requirements, we produce high-tech powders as fine as 20 microns. For rubber and elastomers, we offer every process step you require, from bale shredding to the production of free-flowing granulate, fine grinding and blending.

Pharmaceutical finishing

High-end production in the clean room

All powders that will come into any kind of contact with people have to meet the highest safety and cleanliness requirements. This is all the more true if the powders are destined for consumption.

This is an area where Dressler Group's wealth of experience really comes to the fore. Because DG has always made cleanliness and purity top priorities in production. It's one of the main reasons why DG develops and manufactures most of its equipment itself. Grinding and blending are two of the core services Dressler Group offers under pharmaceutical conditions.

3D printing

Giving ideas a form: Dressler Group optimises plastic powders for 3D printing

Dressler Group has also made a name for itself as a specialist in grinding and finishing plastic powders for the 3D printing/additive manufacturing industry. As of 2017, DG is a Preferred Partner of HP, one of the world's largest manufacturers of PCs and printers. DG develops and produces powders for the HP Multi Jet Fusion 3D printers as well as for other manufacturers and additive manufacturing processes such as laser sintering.